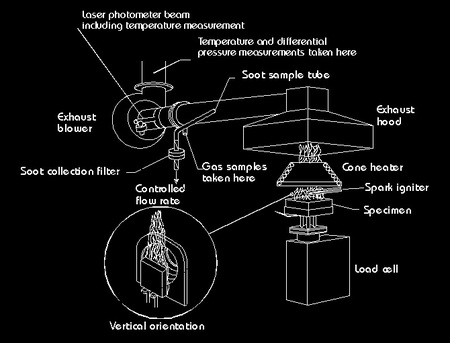

The Cone Calorimeter

The cone calorimeter is a bench-scale apparatus which can monitor the heat release rate, ignition, weight loss of the sample during combustion, effective heat of combustion, rate of smoke generation, carbon monoxide, carbon dioxide, HCl and HBr. The latter data provides scope for further analysis in other areas such as the levels of corrosive and toxic species contained in Intumescent coatings. It is intended to collect all of the mentioned data however, subsequent toxicity analysis will not be conducted during this project due to time constraints.

The concept of the cone calorimeter is based on the findings that the net heat of combustion is proportional to the amount of oxygen required for combustion. Specimens in the test are burned in ambient air conditions, while being subjected to a predetermined external irradiance within the range 0 kW/m2 to 100 kW/m2 and measurements are made of oxygen concentrations and exhaust gas flow rates.The test method is used to assess the contribution that the product under test can make to the rate of evolution of heat during its involvement in fire (ISO 5660). Cone Calorimeter tests are generally performed in accordance with national and international standards, including BS 476 (Part 15), ASTM E1354 and ISO 5660-1. Specimens are normally 100 x 100 mm, with the depth of the steel and thickness of intumescent coating dependant on required data. Thermocouples placed in the sample collect the raw data, on the surface and base of the samples.