"A man should look for what is, and not what he thinks it should be" Albert Einstein

Proof by Experiment

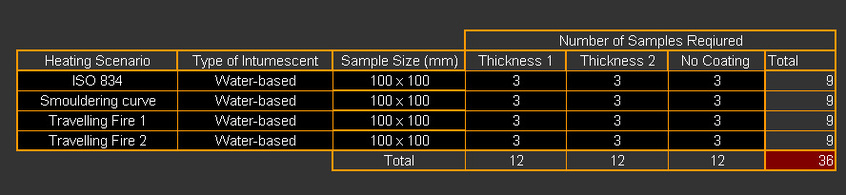

It is intended to test thirty-six coated steel plate specimen samples i.e. nine for each of the four heat scenarios. A further four "uncoated" plate samples will be required for control tests. Hence in total forty tests will be performed over the course of our research (table 1). It is anticipated that each test will be approximately one and half hours in duration, however this will be confirmed during the preliminary experiment stages (see phase 3 below) and the research programme will be adjusted accordingly.

We have been advised by Michal Krajcovic, the University of Edinburgh fire laboratory technician, that the fire laboratory, and the relevant apparatus, will be available for at least two days per week. We envisage the overall duration of the practical stage (see phases 3 & 4 below) to be between nine and ten weeks. These stages are critical stages and determine the duration/punctual completion of our research.

We have been advised by Michal Krajcovic, the University of Edinburgh fire laboratory technician, that the fire laboratory, and the relevant apparatus, will be available for at least two days per week. We envisage the overall duration of the practical stage (see phases 3 & 4 below) to be between nine and ten weeks. These stages are critical stages and determine the duration/punctual completion of our research.

Provisional Outline of Experimental Research

Phase 1: Introduction to Equipment - Status: Phase Completed

In essence, the purpose of this phase is to become familiar with the fire laboratory and its equipment capabilities. Michal Krajcovic, the University of Edinburgh fire laboratory technician, recently gave us an introduction to the basic principles, capabilities and operation of each piece of apparatus. In any research programme it is vital to establish the reliability, accuracy and repeatability of each instrument. This practical training, and further literature reviews, will help in planning of future experiments.

Phase 2: Further Planning and Research - Status: Ongoing

Define hypothesis. Ensure all experiments effectively test hypothesis. Analyse any secondary data already available. Seek supervisor approval and discussion on any plans/ideas.

Phase 3: Preliminary Experiments and Control Tests - Status: Due to Commence on Week 8/9 (Semester 1)

Trial tests will be carried out to calibrate, and also to learn the correct operating procedures, of the apparatus. This phase will validate and further develop our understanding into the effects of variable heat flux on samples and also, importantly, any biases/imitations of the apparatus which will reduce systematic errors.

Control tests will be performed on uncoated samples. The samples will be sprayed with a black dull coating to ensure that the samples have an emissivity value as close as is possible to 1 i.e. ratio of energy radiated by cone calorimeter to energy radiated by sample at the same temperature. A true black body has an emissivity value of 1. The objective of the control tests is to develop appropriate incident heat flux equivalence curves, for each of the four different fire scenarios and to also provide an insight into the workings of the equipment. The control tests will require four steel samples, one for each heating scenario. The samples in the control tests will be exposed to all the same conditions.

Phase 4: Actual Experimental Investigations - Status: Due to Commence on Week 4 (Semester 2)

The full experimental analysis will take place, once the relative incident heat flux acting on the samples has been determined and calibrated. Our Industrial partner will provide over thirty 100mm x 100mm pre-coated steel plates with attached thermocouples to the "cold side" and "hot side". Each thermocouple will generate an output voltage that is proportional to the temperature difference between adjacent thermocouples. Provided that errors are avoided, this temperature difference is proportional to the heat flux. The purpose of the thermocouple is to provide a temperature profile of the steel plates behaviour during each test and thus it can be determined if the intumescent coating is preventing the steel plate from reaching it's critical core temperature i.e. the temperature at which failure and/or collapse would occur in a real life scenario.

During each test all variables will remain constant except temperature. Two separate intumescent coating thickness's will be analysed. These thickness of the intumescent coating will be dependant upon the requirements of a parallel research project being carried out in the University of Edinburgh with the same industrial partner.

In order to ensure accuracy and reliability, each heating scenario test will be performed three times per sample. Overall, four fire scenarios will be analysed.

Phase 5: Discussion, Interpretation and Analysis - Status: Due to Commence on Week 5 (Semester 2)

The analysis of the collected primary data will be one of the most important phases of the research. Ultimately, primary data collected from the experimental analysis will be analysed to determine the performance of the intumescent coating in the four heating scenarios. Toxicity levels and corrosive species contained in the intumescence coatings will also be collected. However, subsequent toxicity analysis will not be conducted during this project due to time constraints.

In essence, the purpose of this phase is to become familiar with the fire laboratory and its equipment capabilities. Michal Krajcovic, the University of Edinburgh fire laboratory technician, recently gave us an introduction to the basic principles, capabilities and operation of each piece of apparatus. In any research programme it is vital to establish the reliability, accuracy and repeatability of each instrument. This practical training, and further literature reviews, will help in planning of future experiments.

Phase 2: Further Planning and Research - Status: Ongoing

Define hypothesis. Ensure all experiments effectively test hypothesis. Analyse any secondary data already available. Seek supervisor approval and discussion on any plans/ideas.

Phase 3: Preliminary Experiments and Control Tests - Status: Due to Commence on Week 8/9 (Semester 1)

Trial tests will be carried out to calibrate, and also to learn the correct operating procedures, of the apparatus. This phase will validate and further develop our understanding into the effects of variable heat flux on samples and also, importantly, any biases/imitations of the apparatus which will reduce systematic errors.

Control tests will be performed on uncoated samples. The samples will be sprayed with a black dull coating to ensure that the samples have an emissivity value as close as is possible to 1 i.e. ratio of energy radiated by cone calorimeter to energy radiated by sample at the same temperature. A true black body has an emissivity value of 1. The objective of the control tests is to develop appropriate incident heat flux equivalence curves, for each of the four different fire scenarios and to also provide an insight into the workings of the equipment. The control tests will require four steel samples, one for each heating scenario. The samples in the control tests will be exposed to all the same conditions.

Phase 4: Actual Experimental Investigations - Status: Due to Commence on Week 4 (Semester 2)

The full experimental analysis will take place, once the relative incident heat flux acting on the samples has been determined and calibrated. Our Industrial partner will provide over thirty 100mm x 100mm pre-coated steel plates with attached thermocouples to the "cold side" and "hot side". Each thermocouple will generate an output voltage that is proportional to the temperature difference between adjacent thermocouples. Provided that errors are avoided, this temperature difference is proportional to the heat flux. The purpose of the thermocouple is to provide a temperature profile of the steel plates behaviour during each test and thus it can be determined if the intumescent coating is preventing the steel plate from reaching it's critical core temperature i.e. the temperature at which failure and/or collapse would occur in a real life scenario.

During each test all variables will remain constant except temperature. Two separate intumescent coating thickness's will be analysed. These thickness of the intumescent coating will be dependant upon the requirements of a parallel research project being carried out in the University of Edinburgh with the same industrial partner.

In order to ensure accuracy and reliability, each heating scenario test will be performed three times per sample. Overall, four fire scenarios will be analysed.

Phase 5: Discussion, Interpretation and Analysis - Status: Due to Commence on Week 5 (Semester 2)

The analysis of the collected primary data will be one of the most important phases of the research. Ultimately, primary data collected from the experimental analysis will be analysed to determine the performance of the intumescent coating in the four heating scenarios. Toxicity levels and corrosive species contained in the intumescence coatings will also be collected. However, subsequent toxicity analysis will not be conducted during this project due to time constraints.

This website was created, by Connie Leydon and Patricia Lehane, in partial satisfaction of the requirements for the degree of Master of Engineering, in Civil Engineering (Leydon) / Civil & Environmental Engineering (Lehane), at the University of Edinburgh, U.K. ©